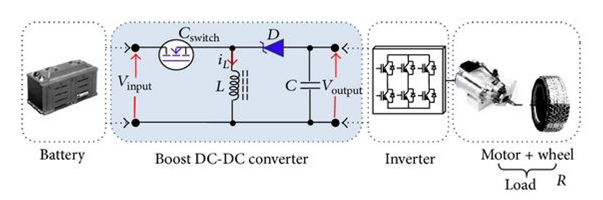

A DC-DC converter converts DC voltage to ensure efficient delivery of voltage from batteries and/or fuel cells tovarious electrical components and drive motors inside a car. Higher efficiency, more energy conservation andcompact size are strongly requested for DC-DC converters, requiring material manufacturers to furnish moreefficient materials with lower power loss.

Product Information –

It is a bidirectional DC/DC converter that can be used to connect a battery to a DC bus. The battery can be charged or discharged via the bidirectional DC/DC converter. The converter has high frequency transformer isolation, high efficiency, high power density and high reliability.

The source side voltage range is 100-360VDC with 15KW power rating. It is an innovative product for energy storage applications.

Unique Functions –

- Bidirectional converter

- Internal High Frequency transformer isolation

- Smooth transition of power flow direction

Main Features –

- Constant current keeps the larger power in source side

- High efficiency higher than 97.5%

- Low standby power consumption, less than 10W

- Maximum 32 converters in parallel

- Plug and Play

- Dual CAN interface

- Wide operation temperature range - 40ᵒC - +70ᵒC

Applications –

- EV charger with Energy Storage

- Smart grid with DC bus and Energy Storage

Unique Functions –

- Bidirectional converter

- Internal High Frequency transformer isolation

- Smooth transition of power flow direction

The battery charger is used for battery charging in various DC outputs. But for Electric Vehicles, chargers aremade for 12V -48V batteries.

EV Charger Types:

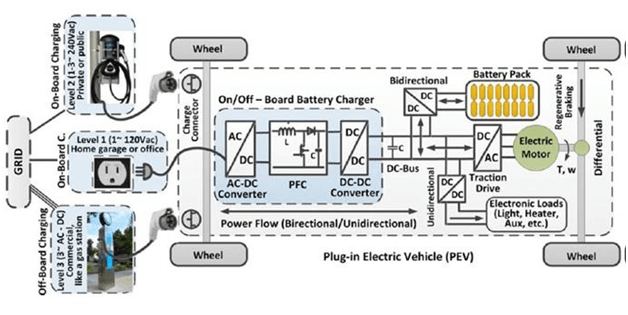

1. On-board charger: The actual charging device for Level 1 and Level 2 charging comes factory-installed and iscalled the “on-board charger.” It converts AC power from the wall to DC power that charges the battery in thevehicle. The charging speed may vary, but the most common on-board chargers are 6.6 kW on battery electricvehicles (BEVs) and 3.3 kW on plug-in hybrid electric vehicles (PHEVs). DC Fast Charging uses its own off-boardcharger.

2 EVSE: Stands for “electric vehicle service equipment.” It is the intermediary between a power source and thevehicle’s charging port, and is typically mounted on a wall or up on a pedestal. Its role is to simply relay the ACpower to the vehicle safely.

Comming Soon.......

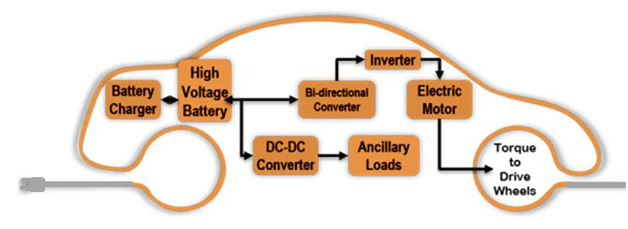

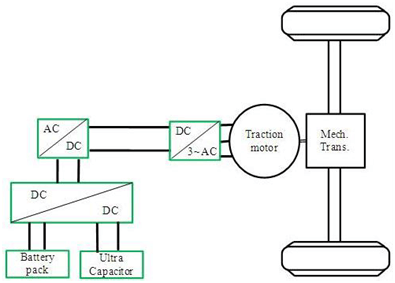

In this figure, it can be seen that the traction motor requires ACinput. The main source of electrical power is the battery which is a DC source. The DC output of the battery isbucked or bossted according to the requirement and then converted into AC using a DC-AC inverter . The functionof an inverter is to change a dc input voltage to a symmetric ac output voltage of desired magnitude andfrequency. The output voltage waveforms of ideal inverters should be sinusoidal. However, the waveforms ofpractical inverters are non-sinusoidal and contain certain harmonics.

#Recommended UAML Cores for Inverter

Zero Phase reactors (Common Mode Choke Cores):

These Zero-Phase Reactors also make the most of the high permeability andstable temperature characteristics of Nanocrystalline Material.The zero-phase reactors are suitable for the radio noise and line noise filtersof various inverter devices, switching mode power suppliers and signal lines.

Power inductor Cores:

Power Inductor Cores (UM GTC) use Fe-based amorphous materials of high saturation flux density and low core loss.Three types with permeability of 100, 245 and 270 are available. They can be used in environments that are exposed toconsiderable vibrations and/or temperature change as power inductorsfor the smoothing of various power supplies and voltage conversion ofDC-DC converters. In addition, they are suitable for manufacturing morecompact coils with lower core loss.