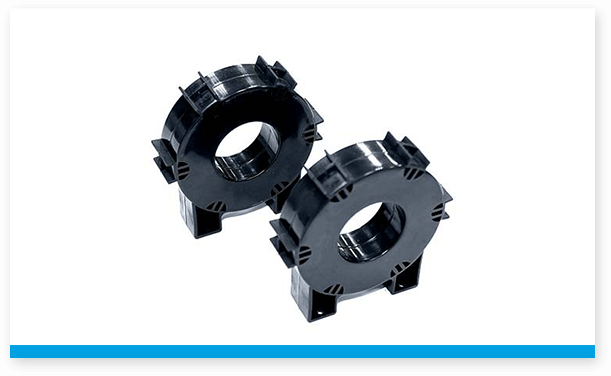

Applications

- Inverter welding machines

- Electrolytic plating power supplies

- High Power Laser power supplies

- Communication, high-speed railway power supplies

- High frequency heating systems

- High frequency and high power switched mode power supply

Benefits

- High saturation flux density – you can reduce volume of transformers vs. traditional Ferrite

- High permeability – improve efficiency, lower exciting power and reduce copper loss

- Low coercivity and Low core loss – low temperature rise

- Excellent thermal stability – working temperature of -40 – 130℃

| Thickness (µm) | 25-30 |

| Stacking Factor | > 0.8 |

| Saturation Flux Density(T) | 1.25 |

| CoreLoss@20KHz,0.2T((W/Kg)) | <4 |

| Permeabilityµ(1KHz) | >50,000 |

| Permeabilityµ{10KHz) | >20000 |

| Permeabilityµ(l00KHz) | >5000 |

| Curie Temperature(℃) | 570 |

| Crystallization Temperature(℃) | 510 |

| Operating Temperature(℃) | -50-130℃ |

| Saturation Magnetostriction(ppm) | 2.7 |

| ElectricalResistivity(µ-ohm-cm) | 130 |

| Coercivity(A/m) | <1.6 |

| Density(g/cm3) | 7.25 |